Additive Manufacturing & Lightweight Construction

The task of lightweight construction is to reduce the weight of components, save material and energy, and increase the recyclability of products while achieving consistent or improved functionality.

Thus, lightweight construction is a transformation technology that leads to a significant increase in energy and resource efficiency along the entire value chain of many industries and companies. Therefore, it makes an important contribution to the sustainability and climate goals of the state of Bremen.

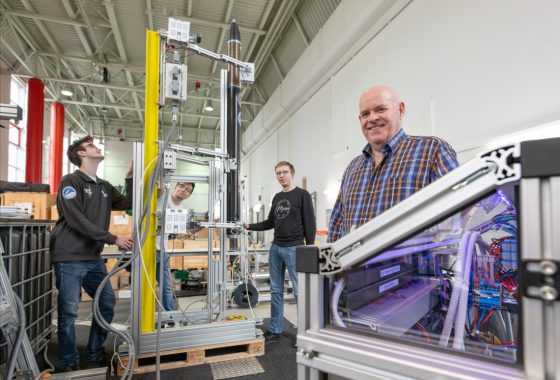

In the state of Bremen, the competencies of business and science in the areas of climate-neutral flying, lightweight construction, innovative materials, surface technologies, 3D printing, and the digitalization of development processes are bundled in the “Center for Eco-efficient Materials & Technologies” - the ECOMAT - in which more than 500 scientists conduct research together. The associated network implements joint projects and exchanges information regularly. Lightweight construction, cryogenic hydrogen, and 3D printing are key technologies that are of great importance due to interdisciplinary and intersectoral cooperation. The researchers' focus is application-oriented.

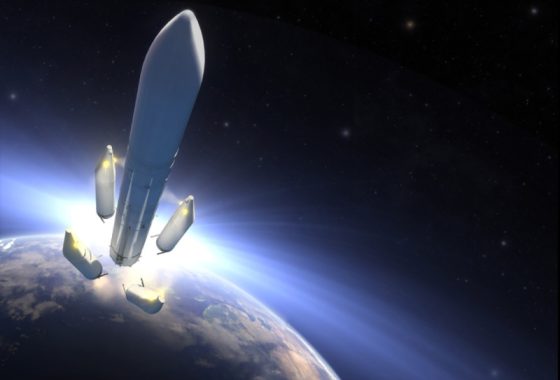

Lightweight construction is a joint task that thrives on interdisciplinary cooperation. Whether in space travel or vehicle construction - new materials are the key to meeting the high demands that the future will place on us.

One of the central themes of ECOMAT is additive manufacturing. Additive manufacturing - colloquially known as 3D printing - has gained in importance like no other manufacturing technology in recent years. With market growth of over 10 percent per year, the industry has been booming for some time. One hotspot in Germany for this is the state of Bremen.

Aerospace is an important driver of innovation for additive manufacturing. In hardly any other industry does weight play as big a role as here. The state of Bremen is a center for European aerospace. OHB, Airbus, and the ArianeGroup are among the best known of the 120 companies based in the state of Bremen. BremerBEGO is also a pioneer in medical technology with around 20 years of experience in the technology. Additive manufacturing is being used industrially in more and more areas. With Materialise's competence center for metallic 3D printing, Bremen has another asset in this area. Also, the scientific expertise in lightweight construction and additive manufacturing is higher in the state of Bremen than in almost any other location. There exist corresponding competencies in Bremen along the entire process chain in the area of materials - processes - bionics. Institutes such as the Fraunhofer IFAM, the Leibniz IWT, the BIAS, the FIBRE, and the ISEMP are located at the University of Bremen. But also the Bremen University of Applied Sciences, in particular with the Bionics Innovation Center, and the AWI in Bremerhaven, with the ELiSE process, have a high level of expertise in bionics.